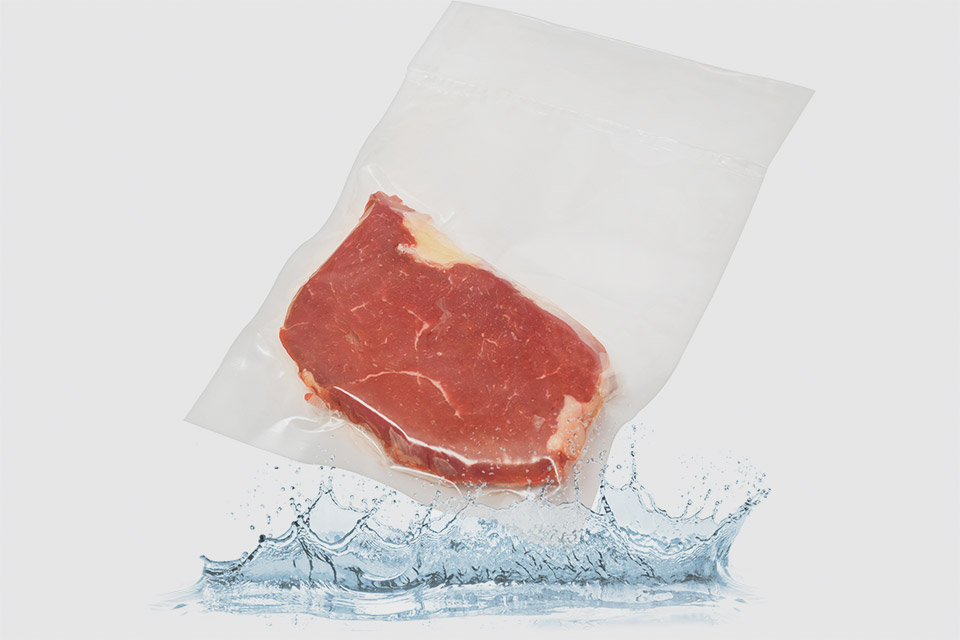

With the high-quality cooking bags from allfo, you can prepare your food perfectly at extreme temperatures from -40°C to +121°C. Thanks to this outstanding feature, vacuum cooking bags offer an impressive range of applications, from boiling to efficient shock freezing, slow cooking in the sous-vide style and industrial pasteurisation and sterilisation. Their flexibility and efficiency make them an indispensable tool for chefs in private and commercial kitchens as well as in the food industry.

The vacuum bags from allfo withstand temperature fluctuations without delamination, loss of tightness, breakage or streaking. This quality standard is crucial for maintaining product quality.

Designed specifically to meet the needs of the catering and industrial sectors, our wide range of cooking bags guarantee unrivalled temperature resistance. Experience perfection in the preparation and storage of your food with vacuum cooking bags from allfo.