Tailor-made bags according to our customers’ specifications provide that your packaging processes are more efficient, time-saving and thus achieve better results. Accordingly, your bags are a top priority for us, which manifests itself in the quality, in the fitting accuracy, their functionality and reliability. These positive characteristics are ensured by the allfo team. We listen intently to you, get an overview of your requirements and finally assemble the bag that fits your applications perfectly. Our confectioning excels by quality, sustainability and delivery dependability within short production times. The vacuum bags are counted, packaged loosely or, at request, sub-packed in cartons. In doing so, we are able to quickly and reliably implement any desired batch size.

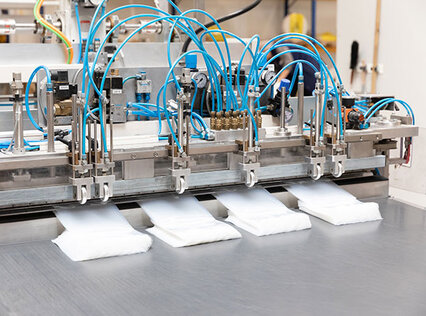

Smooth confectioning of a wide variety of bags

Whether you need side seal bags, tubular bags, multilayer bags, shrink bags, cook-in bags, stand-up pouches, textured bags or printed bags – we always keep a large number of the most common sizes in stock, pallet by pallet, in order to ensure short delivery times for your benefit. Ultimately, your delivery will also depend on our speed in confectioning. It is obvious, that meat, cheese, vegetables or pharmaceutical products demand speed. Our employees work with this understanding and in compliance with the Hygiene and Quality Management Standard to guarantee smooth confectioning on all allfo machines.