Packaging food in allfo vacuum bags prolongs their shelf life, which can be further increased by pasteurisation. Depending on the product, the food is heated to a core temperature of less than 100°C and then reduced to a minimum temperature. In comparison with sterilisation, pasteurisation does not manipulate proteins, vitamins, minerals or the colour of food, while most heat-sensitive microorganisms such as yeast or mould on the surface of the products are destroyed. Milk, liquid eggs or acidic vegetables, fruit or fruit juices as well as meat or meat products – they all benefit from this process.

Pasteurisation in the Sous-Vide process

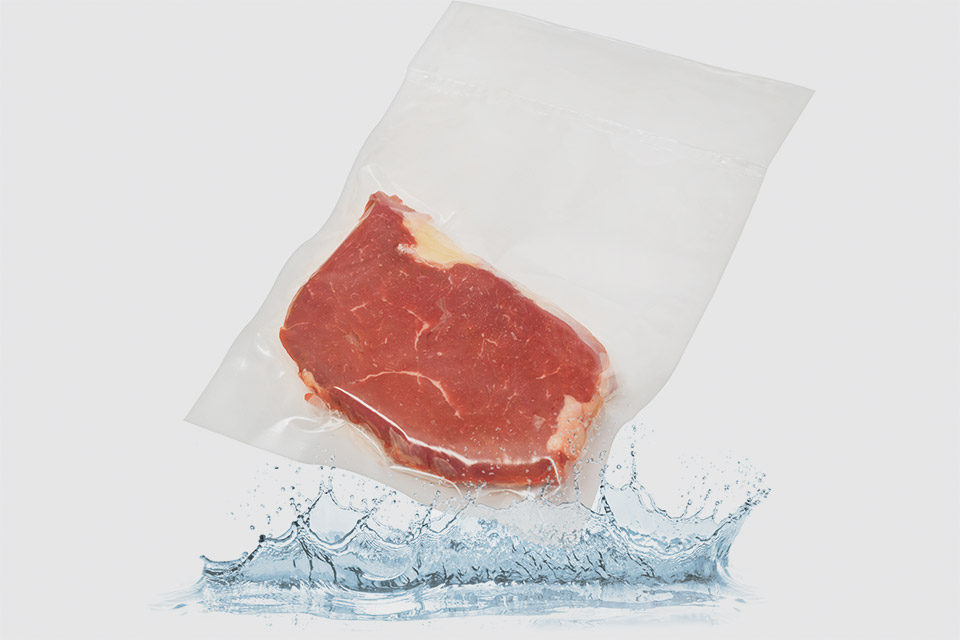

Since the temperature during pasteurisation is usually not particularly high, the process takes up to several hours for the food to be considered safe. Cooking in Sous-Vide has proven to be effective during pasteurisation. Products such as meat, sausage or vegetables are first blanched in hot water, which destroys any germs on the surface. The food is then packaged in a vacuum bag and heated in the Sous-Vide method. Right after, in order to inhibit pathogens from multiplying again, the product must be immediately chilled. For this purpose, the vacuum bags are usually placed in ice water. The duration depends on the type of food.